|

Powerful engine features full-pressure lubrication for long life

A 22-hp (16.4-kW) V-twin engine has plenty of power and torque to handle tough mowing, mulching, and bagging: A 22-hp (16.4-kW) V-twin engine has plenty of power and torque to handle tough mowing, mulching, and bagging: - V-twin cylinder design for greater torque, lower vibration, and improved sound quality

- Electronic ignition for fast starts

- Spring-return feature to ensure the operator does not mistakenly leave the throttle lever in the choke position

- Cast-iron cylinder liners for longer engine life

- Overhead valves for excellent power and fuel economy

- Full-pressure lubrication and oil filter for cleaner oil, prolonging engine life and extending the time between oil changes

- More effective when operating the tractor on an incline

|

Fuel tank Fuel tank - The capacity is 2.4 U.S. gal. (9.1 L).

- The fuel filler opening is conveniently located under the seat.

- Filling the tank without spilling is easy.

- A tethered fuel tank cap is more convenient.

- The sealed fuel cap helps keep vapors inside the tank.

|

|

John Deere Easy Change™ 30-second oil change system

The John Deere Easy Change 30-second oil change system makes changing the engine oil easy, quick, and clean. Changing the oil is as easy as twisting on a new oil-filled filter. Oil does not need to be drained from the engine.

The John Deere Easy Change filter is an additional engine oil reservoir. Changing the filter removes the captured contaminants and replaces about 0.8 qt (0.76 L) of engine oil.

The functionality does not stop with ease of use. The Easy Change oil system has several meaningful benefits over the traditional oil filter system of the 100 Series: - A synthetic filter material is used for more predictable filtering and longer life.

- Filtering capacity is greater than with a standard oil filter.

- More filter surface area

- More oil flow capacity

- The system has 40 percent more oil volume.

- The oil and engine run cooler.

- The oil filter valve closes whenever the engine stops, so filtered particles are captured and cannot drain back into the engine.

- The risk of spilling during oil service is greatly reduced.

- Waste oil (and new oil production) is reduced by over 1,000,000 lb (453,592.4 kg) per tractor production year.

- This system is not a compromise to just make oil changes easier—these engines pass the same John Deere expectations and rigorous testing as always.

Partly due to these improvements, it is not necessary to remove and dispose of all the oil in the engine during service.

Everyone who uses the John Deere Easy Change system saves time and avoids the mess of a traditional oil change. In the past, many 100 Series Lawn Tractor owners rarely or never got around to changing their engine oil. With the 30-second oil change, even people who previously would not consider changing the oil themselves can easily do it. The Easy Change system is a no-mess, no-fuss solution the competition cannot match.

Installation instructions are in the Operator’s Manual and in the John Deere Easy Change service part box.

Please recycle. Many local government recycling programs, authorized retailers, auto-service centers, and auto-parts stores will puncture and recycle used oil filters and oil. |

|

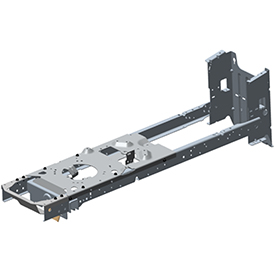

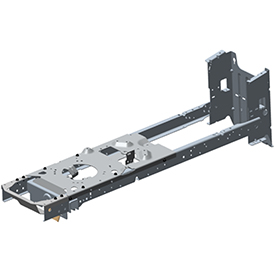

Frame made of full-length welded steel for reliability

The solid one-piece frame is constructed of 12-gauge, 0.105-in. (2.66-mm) steel: - Full-length, robotically welded frame design has high-strength steel rails for added strength and long life.

- One-piece, steel fender deck is bolted to the frame.

|

|

The front axle is constructed of solid cast iron that will not bend:

- Automotive-like steering system with sector and pinion steering gears and single drag link with a tie rod provides a very strong, low-effort, and tight-turning system.

- Three grease fittings, on both steering spindles and center pivot, allow for regular lubrication to help maintain easy steering and minimize wear.

- Large, 0.75-in. (1.9-cm) diameter wheel spindles provide excellent durability.

|

|

Front bumper protects the tractor

The front bumper is included on the S130, S140, S160, S170, and S180. It is available as an optional attachment for the S100, S110, and S120. - Additional front-end protection

- Attractive, bold style

|

|

CargO Mount™ system makes installation of rear bagger and other attachments easy

The CargO Mount system is a combination of front- and rear-mounting points providing convenient and easy installation of the sun canopy, rear bagger, and other attachments. |

|

Snow removal is a strength of lawn tractors Snow removal is a strength of lawn tractors

An advantage of lawn tractors is their ability to use equipment for snow removal. Lawn tractor owners can add a John Deere snow blower or front blade to make quick work of moving snow whenever the need arises. Weather enclosure and tire-chain attachments add comfort and performance.

Equipment available for snow removal includes: - 44-in. (112-cm) Snow Blower

- 46-in. (117-cm) Front Blade

- Tire chains or TerraGrip traction belts

- Weather enclosure

- Weights

|

|

Hydrostatic transmission gives an infinite choice of ground speeds

A Kanzaki® Tuff Torq® hydrostatic transmission gives an infinite choice of speeds and makes changing the direction of travel easy. Side-by-side foot pedals control the speed and direction of travel: - Automotive-type accelerator controls ensure easy operation.

- Operator can change direction without lifting foot off the platform.

- Large pedal surface gives superior operator comfort.

|

|

Appropriate transmissions are used in each model, depending on rear tire size and tractor performance requirements, to ensure excellent performance and reliability: Appropriate transmissions are used in each model, depending on rear tire size and tractor performance requirements, to ensure excellent performance and reliability: - Tuff Torq TLT200 – S100, S110, S120, S130, S140, and S160

- Tuff Torq K46 - S170 and S180

|

|

Operator station designed for comfortable operation

The operator station is designed for operator comfort and easy operation: - Controls are positioned where they are easy to reach and easy to use to control the tractor.

- Steering wheel is positioned and angled to give the operator plenty of room and steering comfort.

- Seat is positioned to provide the most comfortable operator position.

|

Controls are easy to see and use: - Large, three-spoke steering wheel for greater operator comfort and control

- Ignition switch is on the dash for starting ease

Wide footrest areas with non-slip, anti-vibration floor mats are provided for operator comfort: - The wide footrest makes it easier to step over the mower deck while entering or exiting the seat.

- Debris-removing channels help keep the footrest area clean and dry.

|

|

Operator comfort is enhanced with a 15-in. (38-cm) high-back, two-piece seat with an open back: - The open-back seat design keeps the operator cooler

- Especially helpful when operating the tractor for extended periods of time

- Easily adjusted forward or rearward while in the seat

- Seat travel of 5.5 in. (14 cm) and 10 different positions to adjust for operator height

|

|

Two long seat springs give plenty of seat travel to smooth out the ride, keeping the operator comfortable while operating the tractor.

Seat can be tilted forward for protection from the elements and to provide easy access to the fuel tank. |

|

Instruments and controls

The contoured dash has clean, attractive styling: - Controls are color-coded and labeled for easy identification.

- Controls are logically placed and easy to reach.

- The hour meter makes it easy to tell when oil changes and other maintenance should be performed.

- Functional design of the controls provides good appearance and a comfortable feel.

|

|

Side-by-side transmission control pedals

Side-by-side transmission control pedals

Side-by-side foot pedals control the speed and direction of travel: - Automotive-type accelerator controls ensure easy operation.

- Operator can change direction without lifting foot off the platform.

- Large pedal surface gives superior operator comfort.

|

|

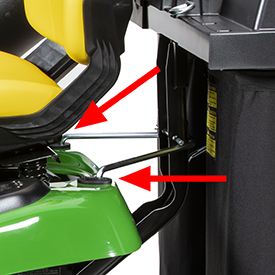

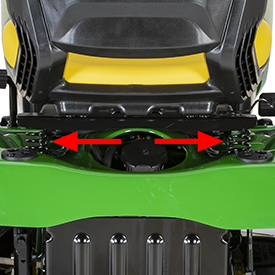

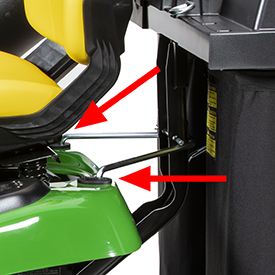

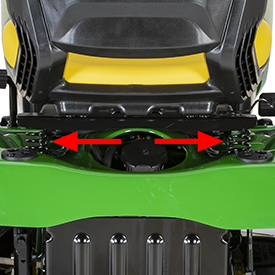

Mower deck height adjustment

Mower deck height adjustment

A spring-assisted, ergonomically designed lift lever simplifies adjusting the mower cut height: - Increments of 1/4 in. (0.64 cm) allow fine-tuning the cut height.

- Cut height is adjustable from 1 to 4 in. (2.5 to 10.2 cm).

- The lift handle is shaped for easy use and is out of the way of entering or exiting operators.

|

|

Parking brake control

Parking brake control

The parking brake control is conveniently located on the tractor pedestal for easy access. It holds the brake pedal securely in the locked position. |

|

Using RIO

CAUTION: Children or bystanders may be injured by rotating blades. Before traveling forward or rearward: - Carefully check the area around the machine.

- Disengage the mower before backing up.

NOTE: Backing up while the mower is engaged is strongly discouraged. RIO should be used only when operating another attachment or when the operator deems it necessary to reposition the machine with the mower engaged.

- Stop forward travel.

- Look behind the machine to be sure there are no bystanders.

- Push and hold in the RIO switch while depressing the reverse pedal slightly.

NOTE: If the engine and mower or other attachment stops while repositioning the machine, return the attachment engagement lever/switch to the off position. Start the engine and engage mower or other attachment. Begin again with step 2.

- Release the RIO switch and reposition the machine as the machine begins to move rearward.

- Resume forward travel. The mower or other attachment should continue operating.

|

Fuel tank

Fuel tank

A 22-hp (16.4-kW) V-twin engine has plenty of power and torque to handle tough mowing, mulching, and bagging:

A 22-hp (16.4-kW) V-twin engine has plenty of power and torque to handle tough mowing, mulching, and bagging:

Snow removal is a strength of lawn tractors

Snow removal is a strength of lawn tractors

Appropriate transmissions are used in each model, depending on rear tire size and tractor performance requirements, to ensure excellent performance and reliability:

Appropriate transmissions are used in each model, depending on rear tire size and tractor performance requirements, to ensure excellent performance and reliability:

Side-by-side transmission control pedals

Side-by-side transmission control pedals Mower deck height adjustment

Mower deck height adjustment Parking brake control

Parking brake control